Hello!

What do you want to search?

ANTAM’s nickel operating segment is comprised of ferronickel and nickel ore sales. Ferronickel production originated from the Company’s Kolaka Nickel Mining Business Unit. Production of nickel ore originated from the nickel mine in Kolaka, Southeast Sulawesi which was operated by the Kolaka Nickel Mining Business Unit, nickel mine in North Konawe which was operated by North Konawe Nickel Mining Business Unit, nickel mine in East Halmahera which was operated by the North Maluku Nickel Mining Business Unit, and nickel mine in Gag Island, West Papua, operated by ANTAM’s subsidiary, PT Gag Nikel.

By the end of 2023, ANTAM's total consolidated nickel reserves were recorded at 489.79 million wet metric tons (wmt), consisting of 103.17 million wmt of limonite ore and 386.62 million wmt of saprolite ore. The total nickel ore reserve position at the end of 2023 grew by 6% compared to the 2022 nickel reserve position of 461.84 million wmt. The growth in ANTAM's consolidated nickel reserves is detailed from measured and indicated resource categories in line with the growth of ferronickel plant operationcapacities, EV Battery downstream initiatives, and the Company's nickel ore sales outlook.

Meanwhile, ANTAM's consolidated nickel resources in 2023 were recorded at 1,309.05 million wmt, consisting of 481.66 million wmt of limonite ore resources and 827.39 million wmt of saprolite ore. Compared to the total resource position at the end of 2022, the nickel resources in 2023 reached 99% of the previous year's position of 1,310.06 million wmt. ANTAM has solid nickel resources to support the Company's operations, especially ensuring the availability of raw materials for ANTAM's nickel processing plant and supporting the Company's nickel-based downstream development projects.

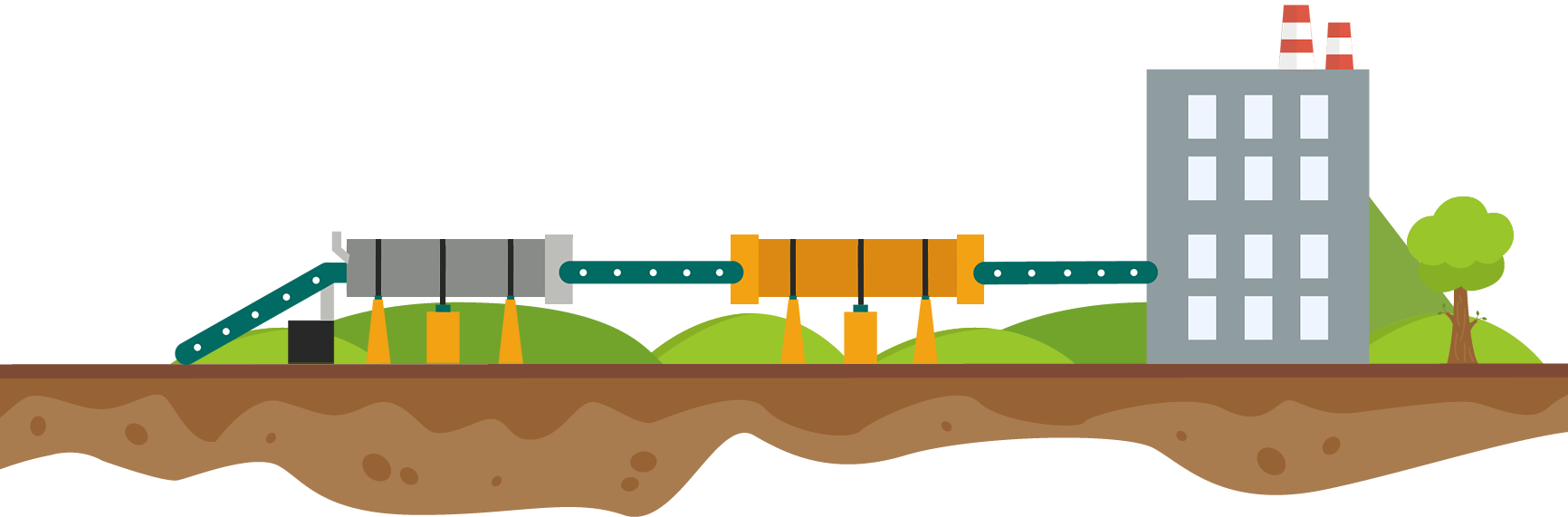

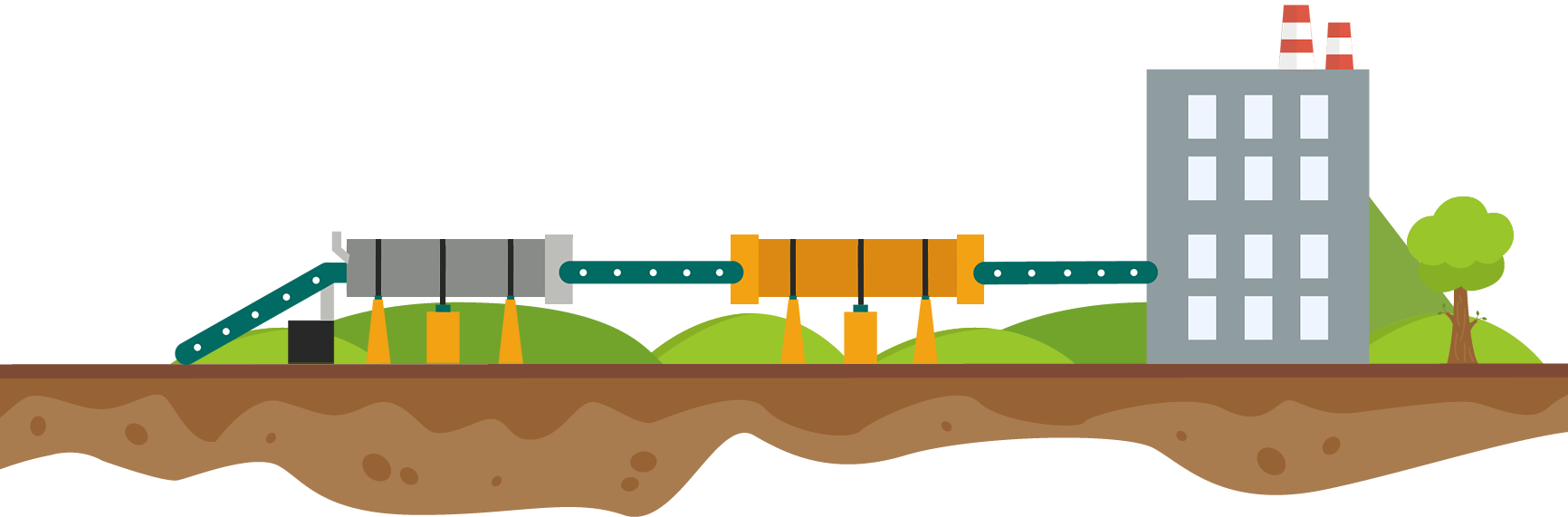

ANTAM's nickel ore deposits are generally not very deep. Limonite nickel ore layer is above the saprolite layer. This makes limonite mining cheaper and limonite mining is complete before saprolite. Nickel ore is mined using the selective open pit mining method with backhoe equipment for excavation and trucks for transportation. No drilling or blasting is required in nickel ore mining or any complicated processing, other than drying and screening ore. In the ore screening process, large ore is obtained which requires additional processing to crush the nickel ore rock to the desired size.

ANTAM conducts open pit mining method with a selective mining to produce high grade and low grade nickel ore. Nickel ore is used for ore feed for Kolaka ferronickel plant as well as being sold to domestic market. ANTAM sun dries its mined nickel ore before being screened to be crushed into desired size. Ore is transported using belt conveyor to the stockpile area before the end of being used in ferronickel processing or transported to domestic customers.

Other products manufactured by ANTAM